Precision on Demand: MT Portable Machine’s FI40E Flange Facing Machine Supports High-Spec Compressor Manufacturing at KOBELCO

Osaka, Japan – June 2025 — In the high-stakes world of compressor manufacturing, precision sealing is critical. Kobe Steel Ltd. (KOBELCO), a leading Japanese industrial group renowned for its advanced compressors, recently partnered with MT Portable Machine, a Wuxi-based portable machining expert, to conduct on-site flange refacing using the FI40E flange facing machine. This collaboration ensured compliance with KOBELCO’s stringent sealing surface standards before shipment.

KOBELCO’s compressors are used in high-pressure and high-temperature environments across petrochemical, LNG, and industrial gas sectors. Consequently, the sealing integrity of each flange surface is non-negotiable. All mating flanges—regardless of size or position—must meet exact flatness and finish specifications. To maintain this high standard without disrupting production flow, KOBELCO opted for in-situ machining directly at the final assembly area.

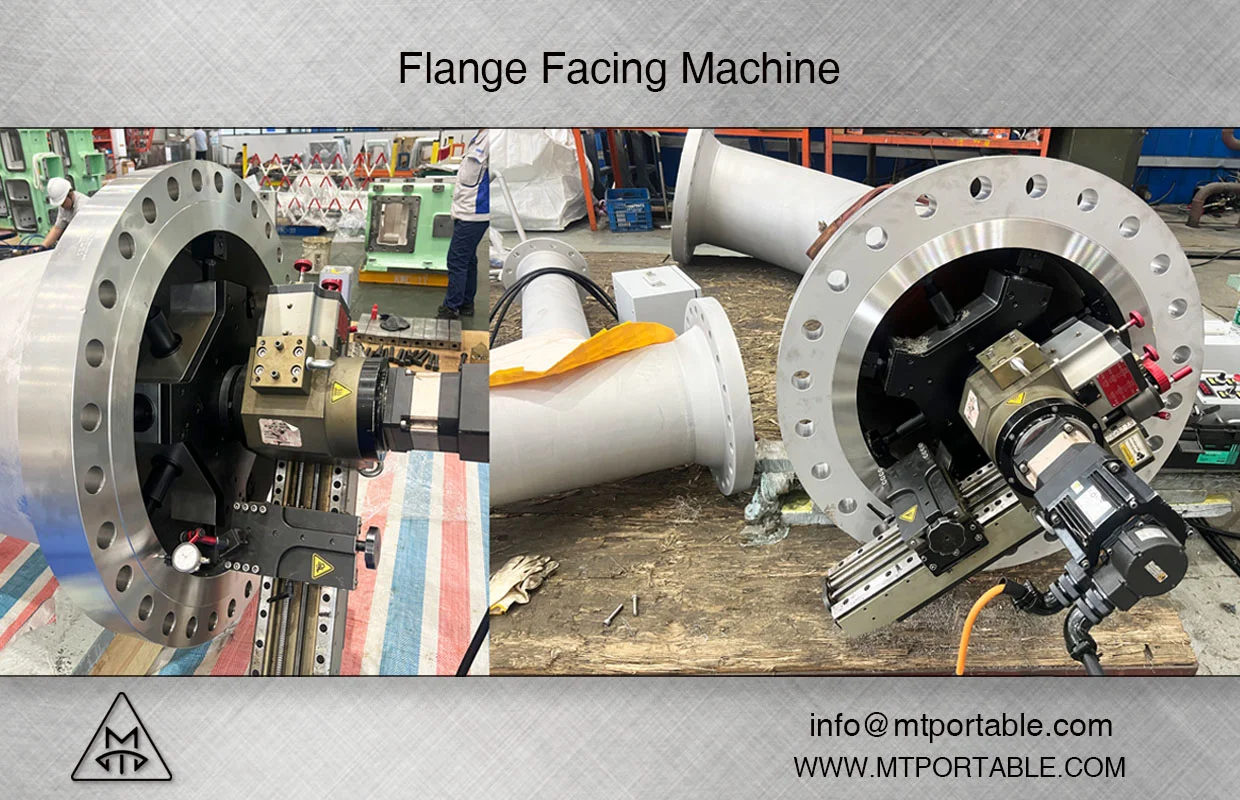

The machine selected for the task was MT’s FI40E, an electrically driven portable flange facer known for its robustness, precision, and modular adaptability. Designed for flanges ranging from Φ153 mm to Φ1000 mm, the FI40E features a rigid feed mechanism, automatic feed, and variable cutting speeds, enabling consistent surface finishes from stock removal to final polish.

The operation was conducted over four days at KOBELCO’s compressor assembly plant in Kobe. The flanges processed included both suction and discharge nozzles on multi-stage axial compressors, with surface finish requirements of Ra3.2 or better. Given the criticality of sealing performance, the target was not only flatness within 0.05 mm but also strict control of spiral tool marks and gasket seating geometry.

“MT’s FI40E proved extremely stable, even under continuous operation. The tool post’s rigidity minimized chatter, and the adjustable feed rate allowed us to match both ASME and JIS sealing profiles—including phonographic and smooth finishes,” said Mr. Tanaka, KOBELCO’s senior QA engineer. “It met our specifications without compromise, directly on-site.”

In addition to equipment performance, MT Portable Machine also provided engineering support, including tooling consultation, setup training, and operational guidance. The compact design of the FI40E enabled technicians to quickly mount the machine on both horizontal and vertical flanges with limited clearance, improving time efficiency.

Eason wang, technical director at MT Portable Machine, commented: “We are proud to support KOBELCO’s zero-defect policy. The FI40E was developed with such high-precision applications in mind—where sealing failure is not an option. This case demonstrates how portable machining can meet OEM-level requirements in real-world production scenarios.”

As demand for precision compressor equipment grows, collaborations like this highlight the value of high-performance portable solutions in modern manufacturing. With tools like the FI40E, companies can achieve factory-level accuracy—anywhere.

www.mtportable.com

Jichuang Machinery Manufacturing Wuxi Co.,Ltd