SRB honed hydraulic cylinder tubes are very strong and precise. They are used in heavy construction equipment. These tubes do not wear out easily. They keep friction low. This helps your machines work longer. Your machines will break down less often. The special honed process makes the surface smoother. It is up to 30% better than regular tubes. This gives your equipment more reliability. You will need less maintenance. About half of hydraulic failures happen because of bad tube quality or finish. Choosing SRB honed hydraulic cylinder tubes is a smart choice. You get better quality and reliability that lasts.

Key Takeaways

-

SRB honed hydraulic cylinder tubes have a very smooth inside surface. This smoothness lowers friction and wear. It helps machines last longer. It also helps them work better.

-

The special SRB process makes tubes stronger. It also makes them more accurate in size. This helps seals work better. It lowers the chance of leaks. It also lowers the chance of breakdowns.

-

These tubes use strong steel grades. They can handle heavy loads. They can also handle high pressure. This makes them great for tough construction equipment. Examples are excavators and bulldozers.

-

SRB honed tubes meet international quality standards. This means they work well in many machines. They also fit easily in machines all over the world.

-

Choosing SRB honed tubes lowers maintenance costs. It also lowers downtime by reducing wear and rust. This saves money. It keeps your equipment running smoothly.

What Is SRB Honed Tube

You want your construction machines to last longer. You also want them to work better. The srb honed hydraulic cylinder tube helps with this. These tubes are more than just metal pipes. They are important parts in hydraulic cylinder systems. You get great precision, strong tubes, and a smooth inside. This helps the hydraulic cylinders move easily. They do not wear out fast, even with heavy loads.

SRB Honed Hydraulic Cylinder Tube Process

Making a srb honed hydraulic cylinder tube uses advanced steps. First, workers cut raw steel tubes. They clean the surface with acid and water. Then, they treat the surface to stop rust. Cold drawing makes the tube stronger and more exact. Heat treatment takes away stress inside the tube. Straightening keeps the tube straight. After cutting to the right size, the main step begins.

The skiving and roller burnishing (SRB) process does two things at once. Skiving blades cut the inside to the right size. Rollers press and smooth the inside surface. This gives a shiny, smooth finish with very low roughness. The finish can be as smooth as 0.25 µm Ra. The tube is now ready for hard jobs and keeps friction low.

|

Description |

|

|---|---|

|

Cutting raw material tube |

Cutting seamless steel tubes first |

|

Acid pickling |

Cleaning and getting the surface ready |

|

Water rinsing |

Washing away acid left on the tube |

|

Phosphating and lubricating |

Treating the surface to stop rust |

|

Cold drawing |

Making the tube smaller and stronger |

|

Heat treatment |

Taking away stress inside the tube |

|

Straightening |

Making sure the tube is straight |

|

Cutting to length |

Cutting tubes to the right size |

|

Skiving & Roller Burnishing (SRB) |

Making the inside smooth and exact |

|

Inspection and packing |

Checking quality and packing tubes |

Honed Tube vs. Other Tubes

It is important to know why a honed tube is better. Honed tubes have tighter sizes and smoother insides than regular tubes. A srb honed hydraulic cylinder tube keeps the inside size within ±0.025mm. The surface roughness stays between 0.2 and 0.4 µm. This means seals work better and last longer. Other tubes, like cold drawn or hot rolled seamless tubes, are not as good. They have rougher insides and looser sizes. This causes more friction, leaks, and faster wear.

|

Tube Type |

Internal Surface Roughness (Ra) |

|---|---|

|

Max 0.25 µm |

|

|

Honed Tubes |

Max 0.40 µm |

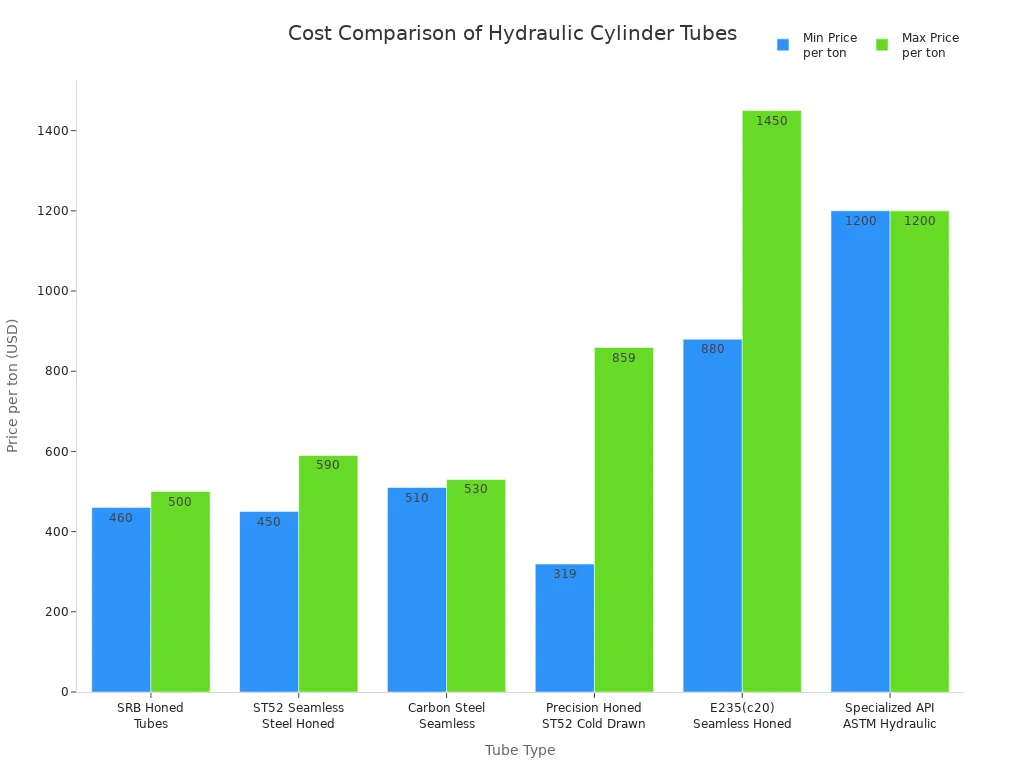

You also want to get good value for your money. The srb honed hydraulic cylinder tube has a good price compared to other types. Look at the chart to see the price difference:

Pick a honed tube for your hydraulic system. You get better performance, longer use, and more value. Your machines deserve the best.

Benefits of Honed Tubes

Surface Finish and Precision

You want your hydraulic cylinders to work well every time. Honed tubes help make this happen. The honing process makes the inside very smooth. It has a cross-hatch pattern. This is not just for looks. The smooth finish holds oil better. This means less friction and less wear on your machines.

Take a look at these numbers:

|

Parameter |

Value |

|---|---|

|

Typical Surface Roughness (Ra) |

≤ 0.4 μm (often 0.25–0.4 μm) |

|

Dimensional Tolerances (ID) |

ISO H8, H9 standards |

|

Straightness |

0.2 – 0.3 mm/m |

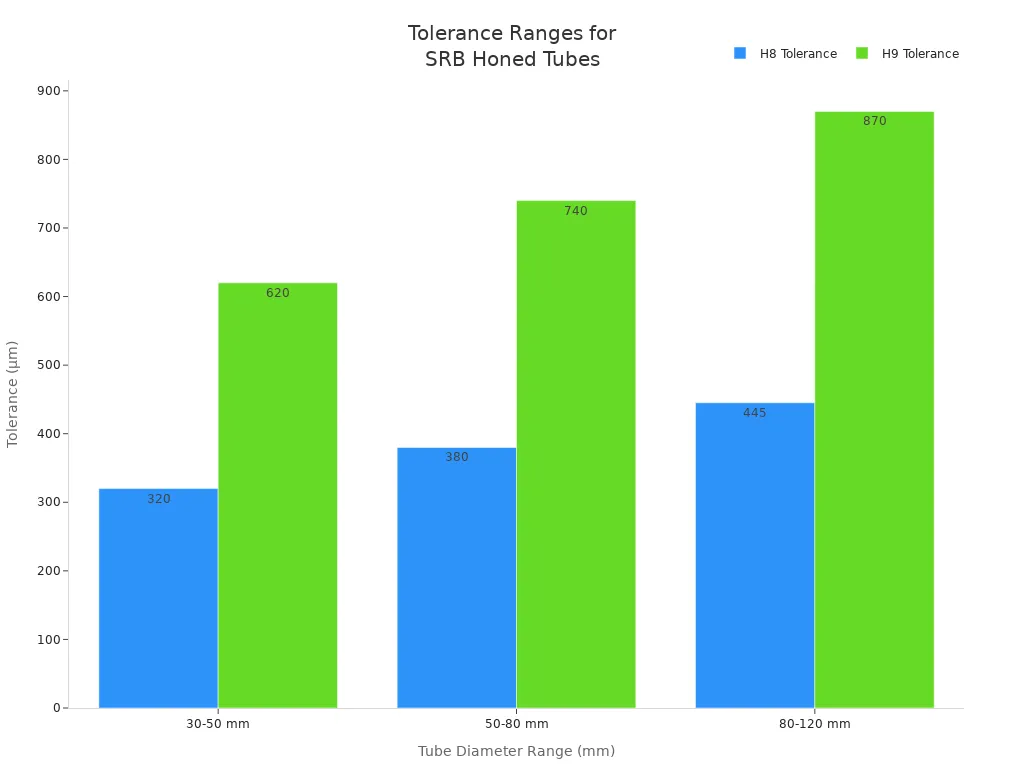

Honed tubes have tight size limits. The inside diameter stays within H8 or H9 rules. This accuracy helps pistons move smoothly. Seals fit just right. You avoid leaks and keep strong hydraulic pressure.

Tip: When you pick honed tubes, you do not need extra machining. The tubes come ready to use. This saves you time and money.

Honed tubes give steady performance. Your hydraulic cylinders will not lose power. They will not leak from a bad fit. You can trust your equipment to work hard every day.

Wear and Corrosion Resistance

You want your construction equipment to last a long time. Honed tubes help you reach this goal. The smooth, hard inside of each honed tube fights wear. It works well even with heavy loads and high pressure. The cross-hatch pattern holds oil. This lowers friction between the piston and the tube wall.

-

The honed surface keeps seals working well. You avoid damage and leaks.

-

Less friction means less heat and slower wear. Your hydraulic cylinders last longer.

-

The accurate size of honed tubes keeps the fit tight. This keeps hydraulic pressure strong.

Honed tubes also fight rust. You can add extra coatings like nitriding or chrome plating. This gives even more protection. Your hydraulic cylinders keep working, even in tough places.

|

H8 Tolerance (mm) |

H9 Tolerance (mm) |

|

|---|---|---|

|

≤ 30 |

+0.033 / 0 |

+0.052 / 0 |

|

30 – 50 |

+0.039 / 0 |

+0.062 / 0 |

|

50 – 80 |

+0.046 / 0 |

+0.074 / 0 |

|

80 – 120 |

+0.054 / 0 |

+0.087 / 0 |

You get more than just a tube. You get a part that helps your hydraulic cylinders work better and last longer. Honed tubes lower downtime. They cut maintenance costs. They help your machines run longer.

Note: Honed tubes are used everywhere for a reason. They give smooth operation, tight size limits, and long-term value for your construction equipment.

www.torichsteel.com

TORICH