In the world of printing, the choice of method can significantly impact the quality, durability, and overall appearance of the final product. This is especially true when it comes to printing on plastic, a material known for its versatility and wide usage across various industries. But what is the best printing method for plastic? The answer isn’t as straightforward as one might think. It depends on several factors, including the type of plastic, the desired finish, and the specific application. This article will delve into the most effective printing methods for plastic, providing a comprehensive guide for those seeking the best results.

- Pad Printing

Pad printing is a popular choice for printing on plastic, especially for irregularly shaped objects. This method uses a silicone pad to transfer the ink from an etched printing plate onto the plastic surface. The flexibility of the silicone pad allows it to adapt to various shapes and textures, making it ideal for printing on items like bottles, toys, and electronic components. However, while pad printing is versatile, it may not be the best choice for large-scale projects due to its slower speed.

- Screen Printing

Screen printing, also known as silk screening, is another common method for printing on plastic. It involves pushing ink through a mesh screen onto the plastic surface. This method is excellent for creating vibrant, high-quality images on flat or slightly curved plastic surfaces. Screen printing is also cost-effective for large volume orders, but it may not be suitable for highly detailed or complex designs.

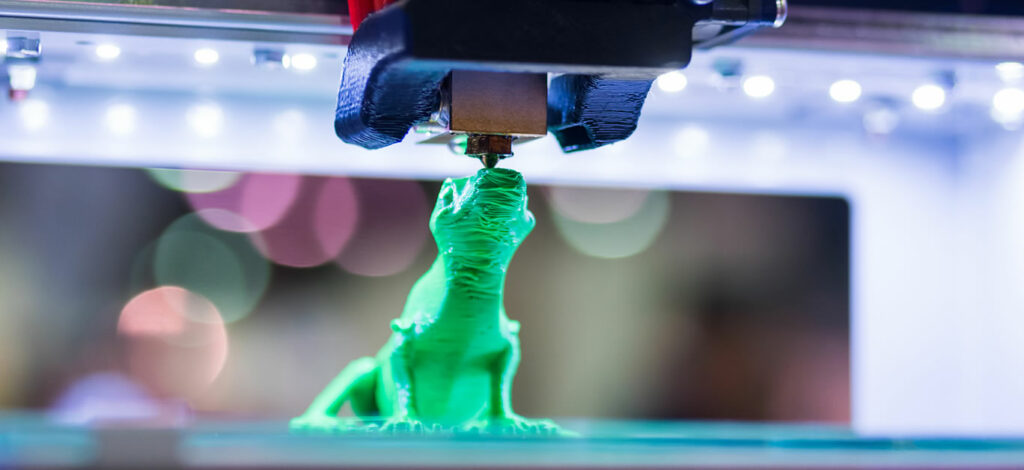

- Digital Printing

Digital printing is a modern method that uses digital files and inkjet or laser printers to print directly onto the plastic surface. This method offers high precision and allows for easy customization, making it ideal for projects that require variable data printing or short-run printing. However, the durability of digital prints may not be as high as other methods, and the cost per unit can be higher.

- Hot Stamping

Hot stamping is a dry printing method that uses heat and pressure to transfer metallic foil or pre-dried ink onto the plastic surface. This method is perfect for adding a luxurious, high-quality finish to plastic products. However, hot stamping is not ideal for large areas or complex designs, and the range of colors is limited compared to other methods.

- Flexography

Flexography, often used in packaging, is a high-speed printing process that uses flexible relief plates and fast-drying inks. It’s excellent for printing on a variety of materials, including plastic. Flexography is ideal for large runs due to its speed and efficiency, but the initial setup cost can be high.

In conclusion, the best printing method for plastic depends on the specific requirements of the project. Factors such as the type of plastic, the design complexity, the production volume, and the budget all play a role in determining the most suitable method. Therefore, it’s crucial to understand the strengths and limitations of each method before making a decision.