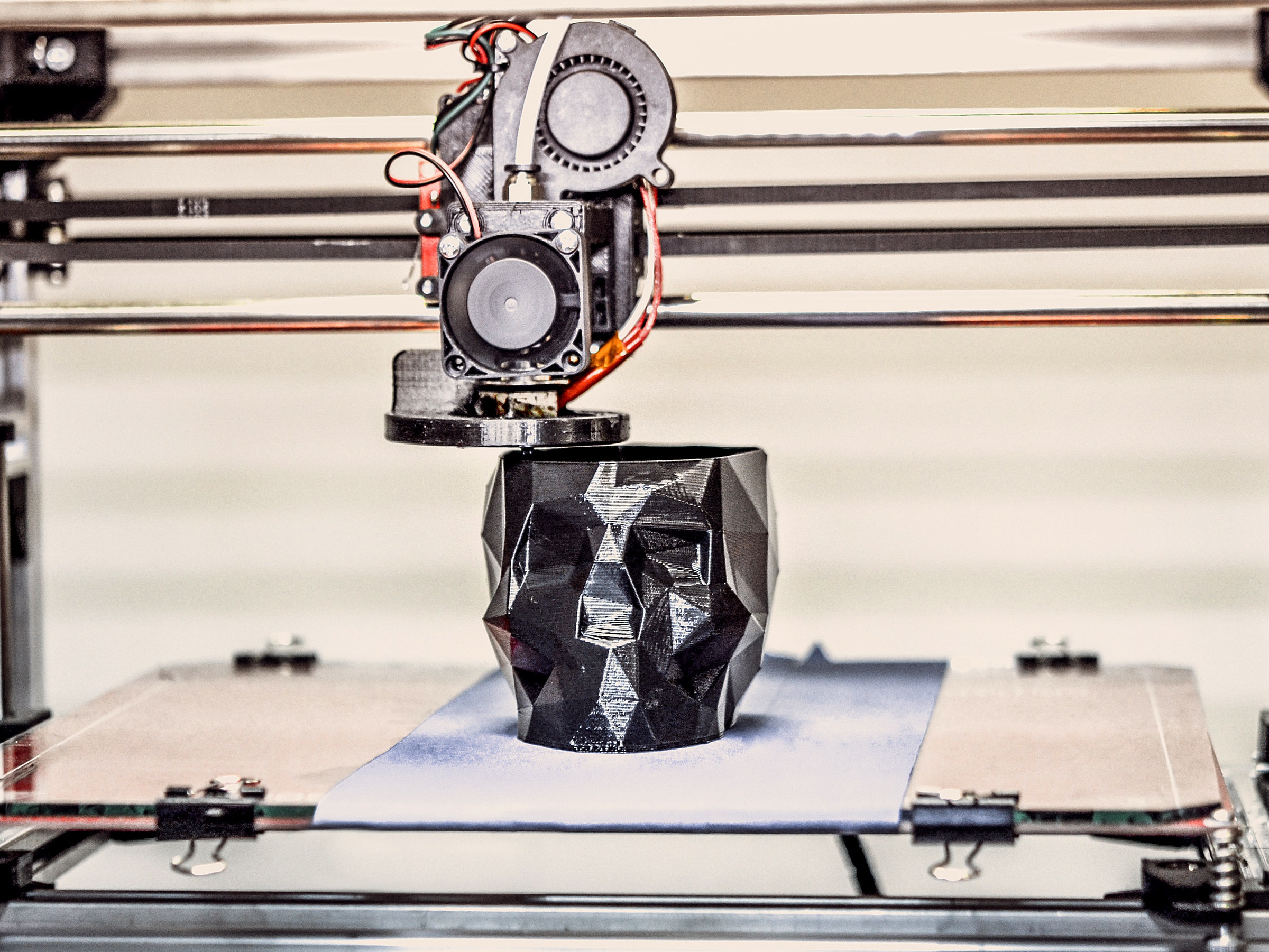

In the ever-evolving world of 3D printing, materials play a crucial role in determining the capabilities and applications of this revolutionary technology. Among the myriad options available, certain materials stand out for their exceptional flexibility, enabling the creation of intricate and functional designs. In this article, we delve into the realm of 3D printing materials and explore the top contenders for flexibility, empowering you with the knowledge to unlock new dimensions of creativity and innovation.

- TPU (Thermoplastic Polyurethane):

TPU, a popular choice for flexible 3D printing, offers an impressive combination of elasticity, durability, and versatility. This thermoplastic material exhibits excellent resistance to abrasion, impact, and chemicals, making it ideal for producing objects that require both flexibility and strength. TPU’s ability to withstand repeated bending and stretching without losing its shape or properties makes it suitable for applications ranging from wearable technology and prosthetics to custom grips and shock-absorbing components. - TPE (Thermoplastic Elastomer):

TPE is another noteworthy material renowned for its flexibility and soft-touch feel. This family of polymers combines the characteristics of rubber and plastic, resulting in a material that can be easily stretched, compressed, and twisted while maintaining its shape. TPE’s versatility extends to various industries, including automotive, consumer goods, and healthcare. It finds applications in gaskets, seals, grips, and ergonomic designs, where comfort and flexibility are paramount. - Ninjaflex (TPU-based Filament):

Ninjaflex, a brand of TPU-based filament, has gained popularity for its exceptional flexibility and ease of use in 3D printing. With its low friction coefficient and high elasticity, Ninjaflex enables the creation of intricate, stretchable designs that can withstand repetitive movements. This material finds applications in areas such as robotics, fashion, and prototyping, where the ability to print complex geometries with flexible properties is essential. - Flexible Resin:

While most 3D printing materials are filament-based, flexible resin offers a unique alternative for achieving flexibility in stereolithography (SLA) or digital light processing (DLP) printers. Flexible resin combines the benefits of resin-based printing, such as high resolution and smooth surface finish, with the ability to produce flexible and elastic objects. This material is particularly useful for creating prototypes, jewelry, and medical models that require intricate details and flexibility simultaneously.

Conclusion:

The world of 3D printing materials is vast and ever-expanding, offering a plethora of options to cater to diverse needs. When it comes to flexibility, TPU, TPE, Ninjaflex, and flexible resin emerge as the top contenders, each with its unique properties and applications. By harnessing the power of these materials, designers, engineers, and innovators can push the boundaries of what is possible, creating functional and aesthetically pleasing objects that were once unimaginable. Embrace the flexibility of 3D printing materials and unlock a world of boundless possibilities.