In the realm of industrial welding, the integration of advanced electrical control systems in welding rotator and turning rolls has revolutionized the way we approach large-scale welding projects. These systems not only enhance precision but also significantly improve operational efficiency. This blog delves into the intricacies of these control systems, exploring their components, functionalities, and the benefits they bring to modern welding operations.

Understanding Welding Rotator and Turning Rolls

Welding rotator and turning rolls are essential equipment in the welding industry, particularly for cylindrical workpieces such as pipes, vessels, and tanks. They facilitate the rotation of these workpieces, allowing for consistent and high-quality welds. The electrical control systems governing these machines are pivotal in ensuring smooth operation, precise control, and safety.

Key Components of Electrical Control Systems

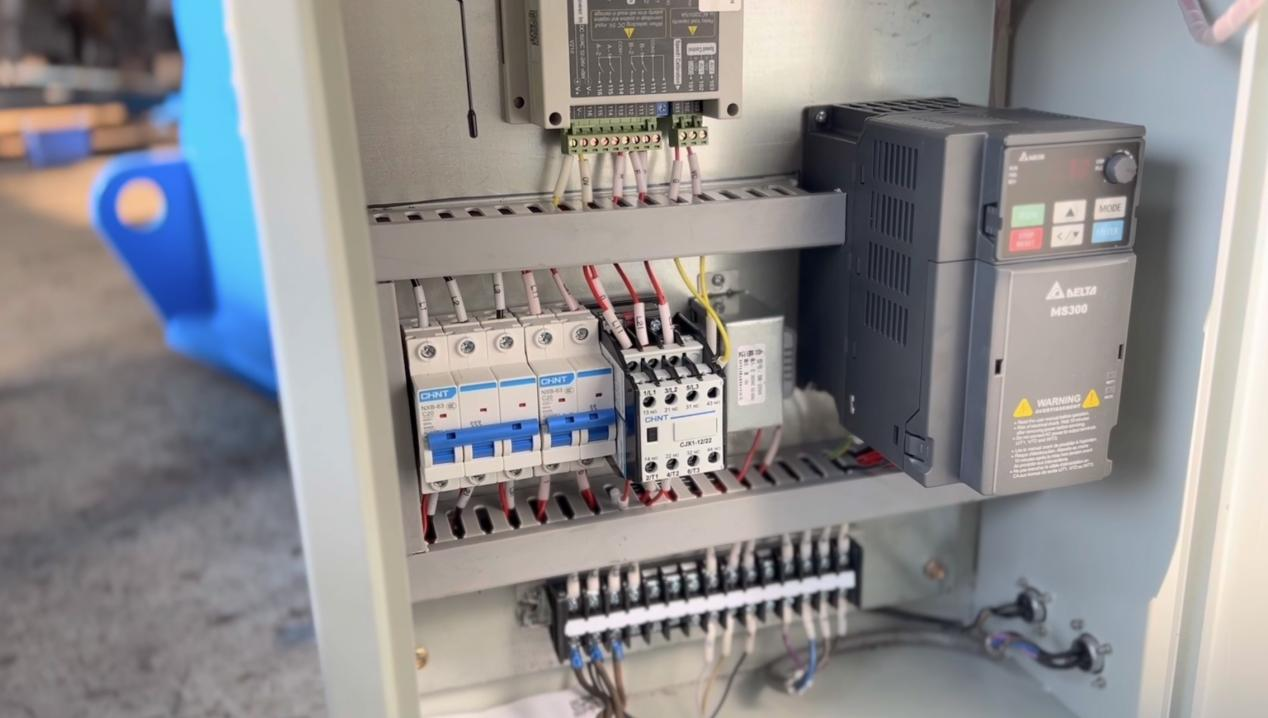

1. Variable Frequency Drives (VFDs): VFDs are crucial in controlling the speed of the motors that drive the rotators and turning rolls. By adjusting the frequency of the electrical supply to the motor, VFDs enable precise speed control, which is essential for achieving uniform weld quality.

2. Programmable Logic Controllers (PLCs): PLCs serve as the brain of the control system. They automate the operation of the welding rotator and turning rolls, allowing for programmable sequences and real-time adjustments. This automation reduces human error and enhances repeatability.

3. Human-Machine Interfaces (HMIs): HMIs provide operators with an intuitive interface to interact with the control system. They display critical information such as speed, torque, and position, and allow for easy adjustments and monitoring.

4. Sensors and Encoders: These components provide real-time feedback on the position and speed of the rotating workpiece. This feedback is essential for maintaining precision and ensuring that the welding process adheres to the specified parameters.

5. Safety Systems: Electrical control systems are equipped with various safety features, including emergency stop buttons, overload protection, and fault diagnostics. These features ensure the safety of operators and the longevity of the equipment.

Benefits of Advanced Electrical Control Systems

1. Enhanced Precision:The ability to precisely control the speed and position of the workpiece results in higher quality welds with minimal defects.

2. Increased Efficiency: Automation reduces the need for manual intervention, speeding up the welding process and allowing for continuous operation.

3. Improved Safety: Integrated safety features protect both the operators and the equipment, reducing the risk of accidents and equipment damage.

4. Versatility: Advanced control systems can be easily reprogrammed to accommodate different welding tasks, making the equipment versatile and adaptable to various industrial needs.

The integration of advanced electrical control systems in welding rotator and turning rolls represents a significant leap forward in industrial welding technology. By leveraging components such as VFDs, PLCs, HMIs, and sensors, these systems offer unparalleled precision, efficiency, and safety. As the demand for high-quality welds continues to grow, the importance of these control systems cannot be overstated. Whether you are involved in pipeline construction, vessel fabrication, or any other large-scale welding project, investing in state-of-the-art electrical control systems is a step towards achieving excellence in welding operations.

www.resizeglobal.com

无锡市远鹏机械设备厂